LIFTKIT vertical axis by SKF Motion Technologies extends reach for UR cobots

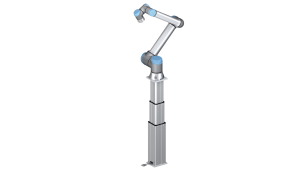

The LIFTKIT vertical positioning axis, produced by SKF Motion Technologies

Universal Robots (UR) has revolutionized industrial automation with its collaborative robot arms, or “cobots”, which are available in Canada through Advanced Motion & Controls Ltd. Now, SKF Motion Technologies has made these robotic arms even more convenient to use – with a special vertical axis to extend their reach.

Certified by UR, the LIFTKIT vertical axis is an easy-to-integrate solution that adds a vertical adjustment to broaden the cobot’s working range.

Perfect for palletizing boxes

The LIFTKIT is an ideal solution for pick-and-place applications, especially box palletizing. When stacking a pallet, the user can lift or lower the cobot vertically to work at a more suitable position. Stacking on pallets can begin at the floor level, and stacks can pile as high as two metres – a working range that is impossible with the robot on its own. This is an effective, smart way to provide a ready-to-mount additional linear axis to a cobot – leading to higher productivity and lower costs.

A ready-to-install system, the LIFTKIT includes a telescopic pillar with a mounting interface to the robot, a controller, and a URCaps software plugin that allows direct motion programming within the UR Polyscope environment. Additional threads are available to attach third-party cable management to the vertical axis. Other features and advantages include the following:

- robust pillar design for industrial use.

- no hardware or software development necessary.

- direct positioning access within the UR control environment.

- vibration-free motion.

- virtually no maintenance required.

The SKF LIFKIT also offers a push load of 1,500 newtons, a maximum stroke of 500 to 900 millimetres, a no-load maximum speed of 80 millimetres per second, IP40 protection, and a duty cycle of ten per cent.

Advanced Motion & Controls Ltd. supplies three sizes of cobots from UR: the UR3, UR5, and UR10. On their own, these robot arms provide maximum reaches from 50 centimetres to 1.3 metres and can handle maximum payloads from three to ten kilograms. With assistance from SKF, these collaborative robots can now reach further than ever before.

To learn more, contact Advanced Motion & Controls.