Expert in Automation

Flexibowl

What is FlexiBowl®?

FlexiBowl® is the flexible parts feeding system for automated production lines using industrial robot or cobots. It is patented and produced by ARS S.r.l. and sold in more than 40 countries worldwide, including through authorized distributors.

FlexiBowl® optimizes parts feeding by ensuring more parts are available for pick-up by the gripper in every cycle. The system improves overall feed rates, increases productivity and reduces changeover times.

How does the flexible system work?

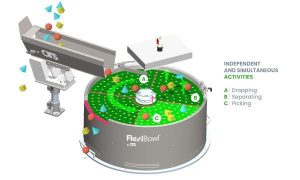

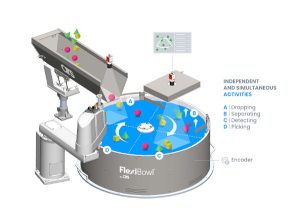

The parts are fed onto a disc by one or more hoppers and positioned optimally. The combined action of the pulse generator and the rotational movement means every single part is quickly stabilized so that the robot can pick and place it as efficiently as possible.

WHY CHOOSE FLEXIBOWL®?

FlexiBowl® orients and separates parts and can be integrated with any vision system and any robot for parts feeding.

The FlexiBowl® system is highly versatile, capable of feeding parts between 1 and 300 mm and from 1 to 300g, regardless of:

• Geometry

• Surface

• Material

Its lack of production-specific tooling and its easy-to-use and intuitive programming permit quick and multiple product changeovers even during the same work shift

Choosing the right model

Make the right choice according to:

• Expected productivity;

• Required orientation of the components that are going to be fed;

• How parts should be set down;

• Overall dimensions and available space;

• Interactions with other features on the production line;

• Reference standards and regulations;

• Characteristics of the production setting

Operating Modes

Traditional operating mode, FlexiTrack, or Multiple Parts Feeding

![]()

Traditional

FlexiBowl® is the only system that has a circular sequence consisting of feeding, rotation, jogging and pick-up. These actions are performed in parallel to prevent stalling, but also to achieve fantastic benefits in terms of efficiency. Perfect for extreme picking precision.

FlexiTrack

The motor and the flip mechanism work continuously to rotate the disc constantly and smoothly. Greater productivity is achieved with a touch less precision. Perfect for parts with simple geometries.

![]()

![]()

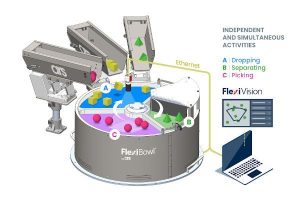

Multiple Parts Feeding

Handles up to 4 types of parts simultaneously. Minimizes layout and production costs in processes that use several parts simultaneously.

Minimizes layout and production costs in processes that use several parts simultaneously

Need You Help For Finding The Right Component?