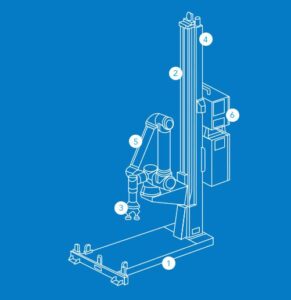

Palletizing solution by Robotiq is set up in three simple steps

Design of the Robotiq palletizing solution

Robotiq is known for its robot grippers, but another innovative product by the manufacturer, available from Advanced Motion & Controls Ltd., is a unique palletizing solution. Blending simplicity with high flexibility, this machine is easy to set up and re-set up quickly, and users can adapt it to their needs with minimal effort. It is also cost-efficient for the operator to do the configuration on his or her own.

Fast return on investment

The customer does not need to design or program the connection between the robot controller and seventh axis or box sensor, as Robotiq has already completed this task. The machine arrives in the box with all of the hardware and software already connected, which saves a substantial amount of time. The manufacturer has also built an environment for safe integration, although third-party safeguard devices are recommended as well.

This palletizing solution is fast to receive, to install, and to set up. No external computer or programming time is required; the user can plan the setup of the application directly on the robot control device in three simple steps. Robotiq provides an application software called Material Handling Copilot, which makes the setup process quick and seamless through a user-friendly platform. All trajectories and robot movements can be generated and automatically optimized with only three pieces of data: box dimensions and weight; pallet dimensions; and pallet pattern.

Due to the high performance cycle time, this palletizing solution from Advanced Motion & Controls earns a faster return on investment than other cobot solutions do. The optimized, synchronized motion control of the robot and seventh axis are a big part of its success, and the seamless movements lead to a longer life cycle. This solution can pick a broad range of box sizes, and cover extensive heights and pallet dimensions, making it perfect for various tasks.

Robotiq offers an online configurator for customers to check if this machine fits their requirements. This solution can fit within any existing floor plan, because of its small footprint, so no reorganization of floor layout is necessary.

To learn more, contact Advanced Motion & Controls.